We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Renewable energy from the ground: The magic of beet processing for biogas production

In the search for renewable energy sources, alternatives to traditional fossil fuels are increasingly being explored. One notable player in this field is beet processing, specifically the conversion of beets into biogas. This innovative approach not only provides a sustainable source of energy, but also contributes to the optimization of agricultural practices.

Fodder beets as feedstock

Beets, originally grown as animal feed, have found a new role in biogas production. These energy-rich crops contain high levels of sugars and starch, which are ideal raw materials for biogas production. Using beets not only makes efficient use of agricultural land, but also creates a sustainable alternative to traditional energy sources.

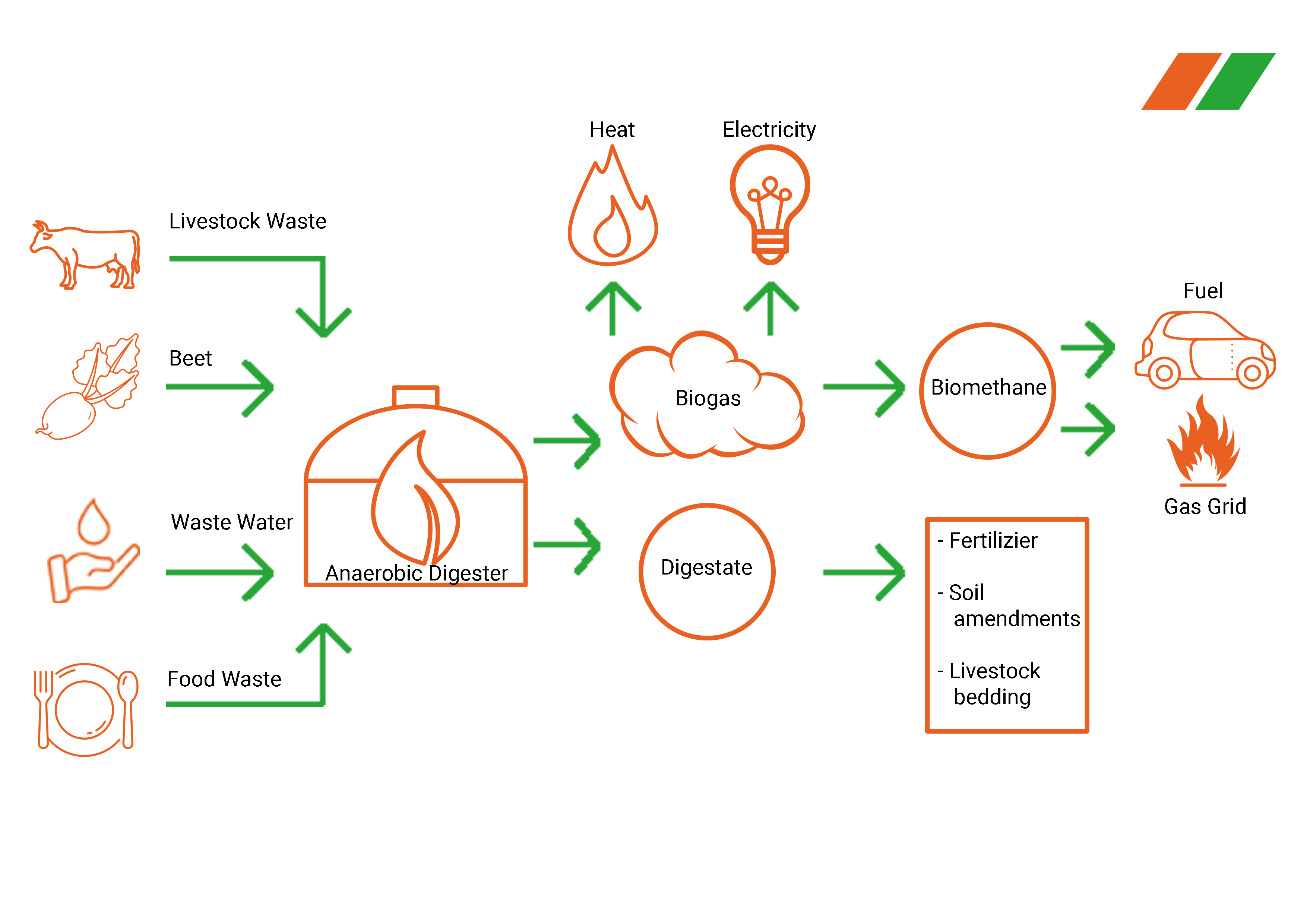

The biogas production process

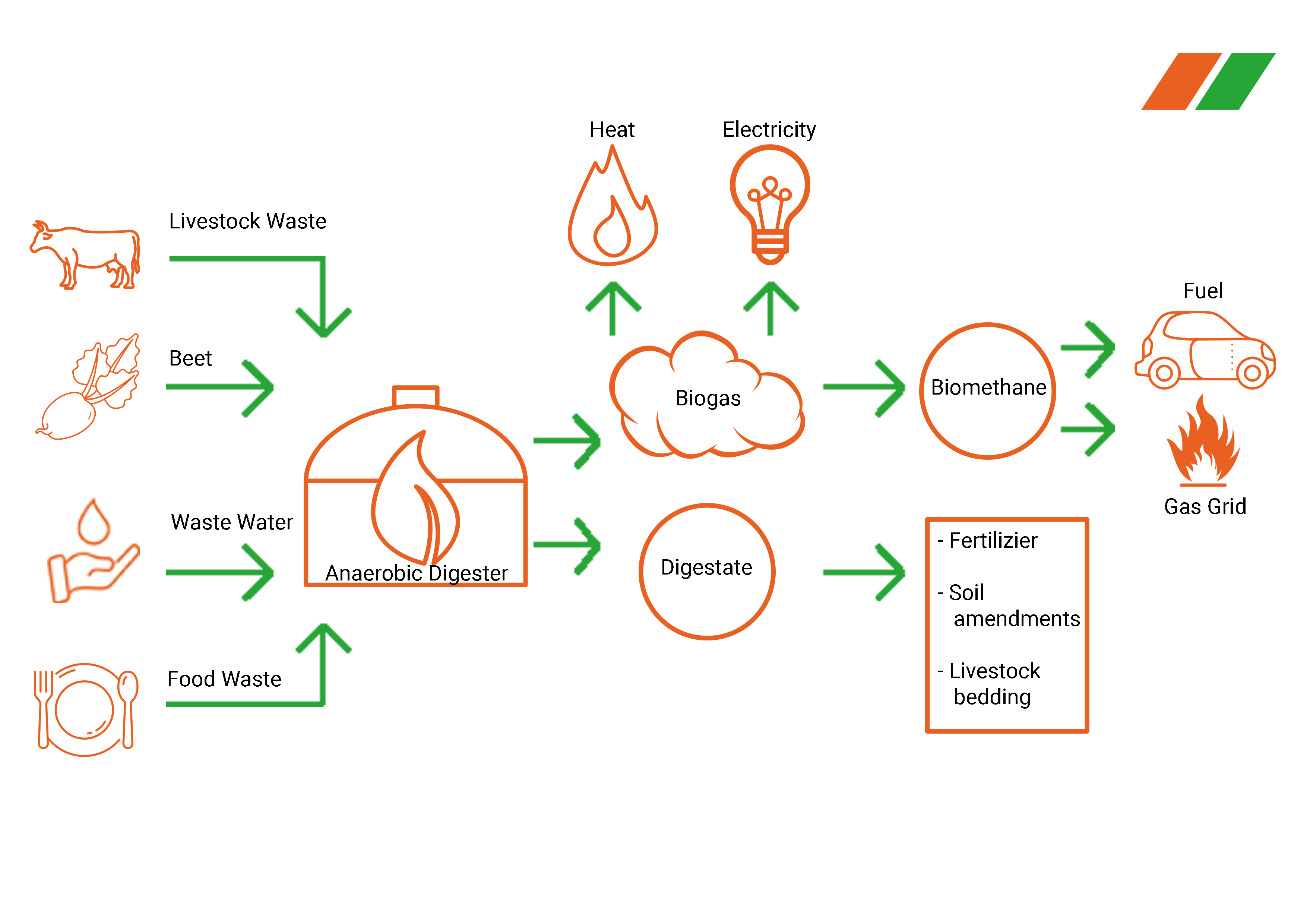

The core of this process is anaerobic digestion, in which microorganisms break down organic material without the presence of oxygen. Energy beets are fed into a biogas plant along with other organic materials. The microorganisms break down the biomass and produce biogas as a byproduct. This biogas consists mainly of methane, which can then be used as a fuel for electricity generation or as a heat source.

Sustainability and Environmental Awareness

Biogas production from beets fits perfectly into the growing trend of sustainable agriculture and environmental awareness. The use of renewable energy sources helps reduce greenhouse gas emissions and promotes a more circular economy. It also contributes to the diversification of energy supply, which is essential for a resilient and sustainable future.

Maize yields 55 tons/ha at 185 m³/ton = 10,000 m³ of biogas/ha.

sugar beets have higher yields on average:

sugar beets yield on average 85 tons/ha x 123 m³/ton = 10,000 m³ of biogas/ha.

Fodder beets are wetter (15% dry matter). They deliver 100 to 110 tons/ha x 85 m³/ton = 9000 m³ biogas/ha.

* Wageningen University & Research: Boerenbond • Management&Techniek 21 • 7 december 2012

Precise processing

The magic of beet processing for biogas production is made possible by advanced technology, such as beet cutters. These innovative machines play a crucial role in efficiently reducing feed beets to the right size for the anaerobic digestion process. By using beet cutters, farmers can increase throughput and ensure that the fodder beets are optimally utilized in the biogas plant.

Maximum convenience with Holaras beet cutters

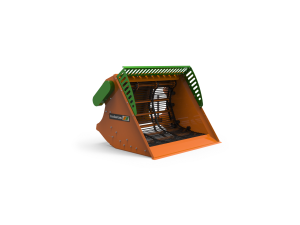

Four jobs in one pass! The robust Holaras beet cutters are suitable for tractor linkage, shovel or front loader attachments.

These beet cutters are not just machines; they offer a solution for a variety of tasks. Whether you want to ensile cut beets with corn or prepare daily fresh feed for your livestock, Holaras beet cutters make it possible.

In addition, these versatile machines come in handy when filling your biogas plant with chopped beets. The specially developed cutting roller at the bottom of the cutting ensures that the beets are perfectly cut and evenly distributed. Our machines also clean the beets first and the sand is then removed from the beets before cutting, this can be done with the beet cleaner/cutter BRS 1250.

Cutting beets with these beet cutters preserves the structure of the beets while minimizing energy consumption. In short, with the Holaras Beet Cutters you combine efficiency and quality in one operation!

Bij een goede oogst horen kwaliteit machines

Hoopman Machines is specialist in het ontwikkelen en produceren van Holaras machines voor de uienverwerking. De uienloofmaaiers, uienrooiers en uienafstaartmachines zijn robuust gebouwd en voorzien van de nieuwste technieken. Speciaal ontworpen voor een efficiënte en nauwkeurige verwerking van uien.

Holaras beet cutter

Gerelateerde artikelen

de

de  nl

nl