Combideal!

Profiteer nu van de gras en mais combideal! De actie is geldig t/m 31 mei 2024.

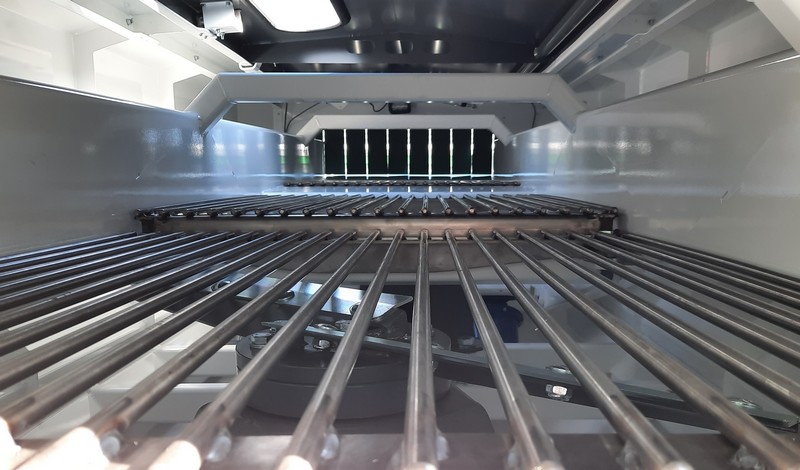

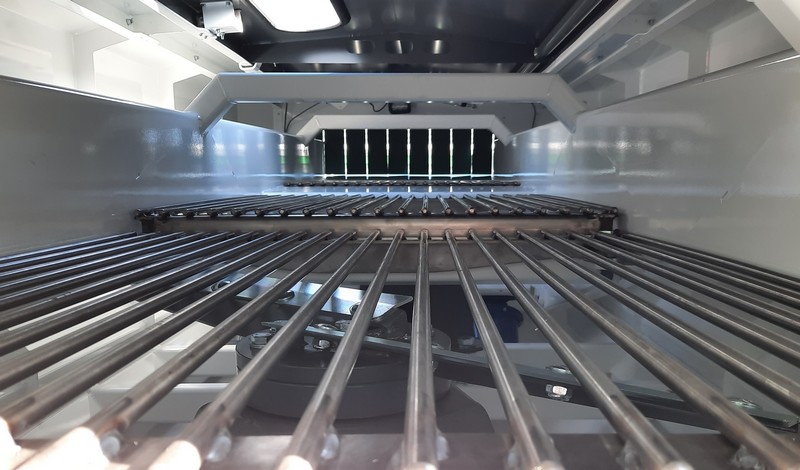

The onion topper is specially designed for trimming onions and bulbs. The high speed and the special shape of the blades create a strong airflow. This airflow sucks the onion tails between the bars of the vibrating screen, after which they are cut off by the sharp blades just under the screen.

All versions are available with closed air circulation and discharge belt. The trimmers are equipped with internal lighting and are supplied as standard with an automatic switch box. The standard passage size of a screen is 28 mm.

The new Onion topper models were introduced in March 2021. Unique features of this revamped series are the new vibrating technology, ergonomic operation due to the addition of a large roof hatch, the lighter sieves, and the ease with which the robust sieves and blades (short service life) can be replaced. The blades can be changed from the side by opening the large roof hatch, which is fitted with a mechanical security lock. The rubber shielding with the Foodsafe quality mark is also new. If pieces of rubber crumble, they can be detected by systems used in the food processing industry.

All trimmer models are available with closed air circulation, discharge belt, and a complete set of sieves.

Vibrating screens for special onion plants are available as an option. Other options are a raised lower frame and frequency-controlled blade motors.

![]() Standard

Standard![]() Optional

Optional![]() Not applicable

Not applicable

| Type | AS 10 | AS 15 | AS 25 |

|

|

|

|

|

| Capacity | 5-10 ton/hour | 10-15 ton/hour | 20-30 ton/hour |

| Number of knives | 2 | 3 | 6 |

| Number Of Sieves | 2 | 3 | 6 |

| Open system, follow the safety guidelines | |||

| Variable frequency controlled vibrating motors | |||

| Variable frequency controlled blade motors | |||

| Free-standing switch box | |||

| Various screen sizes | |||

| Discharge belt extension | |||

| Remote control | |||

| Dampening input | |||

| Preparation for extraction |